In waste management and recycling industries, securing compressed materials efficiently is crucial for storage, transportation, and overall operational efficiency. Bonded (textile) strapping has emerged as an innovative and reliable solution for waste balers and compactors, offering a combination of strength, flexibility, and safety. Unlike traditional steel strapping, bonded textile strapping provides numerous advantages, making it the preferred choice for businesses looking to optimize their waste-handling processes.

What Is Bonded (Textile) Strapping?

Bonded (textile) strapping is made from high-tensile polyester fibers bonded together with adhesive, creating a durable and flexible strapping solution. This type of strapping is designed to handle high tension loads, ensuring that compressed waste materials remain securely fastened. It is commonly used in recycling facilities, manufacturing plants, and distribution centers where waste is compacted for easy handling and disposal.

Key Features of Bonded (Textile) Strapping

1. High Strength and Durability

Bonded textile strapping is engineered to withstand heavy loads and high tension, making it ideal for securing compacted waste materials such as cardboard, plastics, and aluminum cans. Its strong polyester fibers offer excellent resistance to tearing and stretching, ensuring that bales remain securely bound.

2. Flexibility and Shock Absorption

Unlike steel strapping, which is rigid and prone to breaking under sudden impact, bonded textile strapping offers superior shock absorption. This flexibility is particularly important during transportation, where vibrations and sudden movements can compromise the stability of bales.

3. Safety and Ease of Handling

One of the most significant advantages of bonded (textile) strapping over steel strapping is its safety. Steel strapping has sharp edges that can cause serious injuries during handling, while bonded textile strapping is soft and safe to touch. This reduces the risk of workplace accidents and makes it easier for workers to apply and remove the strapping.

4. Corrosion and Weather Resistance

Unlike steel strapping, which can rust and degrade when exposed to moisture, bonded textile strapping is resistant to corrosion, humidity, and extreme weather conditions. This makes it an excellent choice for both indoor and outdoor waste management applications.

5. Lightweight and Cost-Effective

Bonded textile strapping is significantly lighter than steel strapping, reducing shipping costs and making it easier to handle. Additionally, it is a cost-effective solution due to its durability and reusability, helping businesses save on operational expenses.

Applications of Bonded (Textile) Strapping in Waste Balers and Compactors

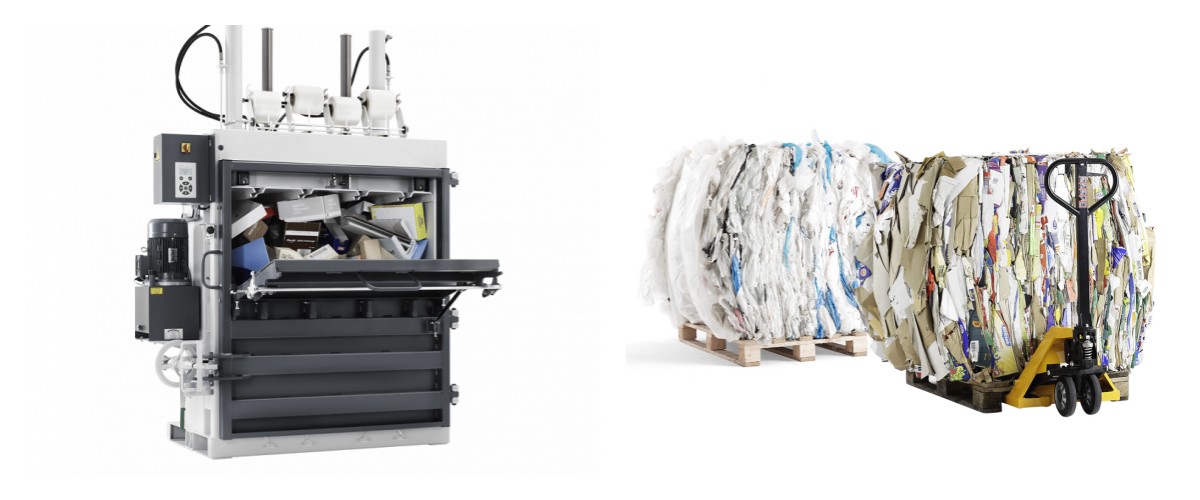

Bonded textile strapping is widely used in waste balers and compactors to secure a variety of materials, including:

-Cardboard: Large volumes of cardboard waste are compressed into bales for easy storage and transportation. Bonded textile strapping ensures that these bales remain tightly secured, preventing them from falling apart.

-Plastics: From PET bottles to plastic packaging waste, bonded textile strapping effectively secures compressed plastic materials, maintaining their shape during handling.

-Aluminum Cans: In recycling facilities, aluminum cans are compacted into dense bales. Bonded textile strapping provides the necessary strength to keep these bales intact.

-Mixed Recyclables: For facilities that process mixed waste, bonded textile strapping offers versatility and reliability, adapting to different materials and bale sizes.

Why Choose Bonded (Textile) Strapping for Waste Management?

1. Improved Efficiency: By using bonded textile strapping, businesses can streamline their waste management processes, reducing downtime and increasing productivity.

2. Environmental Benefits: Many bonded textile strapping options are recyclable, making them an eco-friendly alternative to steel strapping.

3. Enhanced Workplace Safety: With no sharp edges and easy handling, bonded textile strapping contributes to a safer work environment.

4. Cost Savings: Reduced maintenance costs, lower shipping expenses, and increased durability make bonded textile strapping a cost-efficient choice for waste balers and compactors.

Conclusion

Bonded (textile) strapping has revolutionized waste baling and compacting, offering a strong, flexible, and cost-effective solution for securing compressed materials. Its durability, safety features, and adaptability make it an ideal choice for recycling facilities, waste management companies, and industries looking to optimize their operations. By switching to bonded textile strapping, businesses can enhance efficiency, improve safety, and contribute to sustainable waste management practices.