As industries around the globe face increasing pressure to adopt sustainable practices, companies are looking for innovative solutions to reduce waste and minimize environmental impact. In the field of packaging and material handling, bale press strapping has emerged as a crucial tool in supporting these efforts. Used extensively in industries like recycling, agriculture, and manufacturing, bale press strapping offers a simple yet effective way to secure bales of materials such as cardboard, plastic, paper, and metals. When combined with eco-friendly materials, bale press strapping becomes a powerful solution for sustainable packaging.

In this article, we will explore how eco-friendly bale press strapping solutions are shaping the future of sustainable packaging, the materials used, and the benefits they provide to both businesses and the environment.

What is Bale Press Strapping?

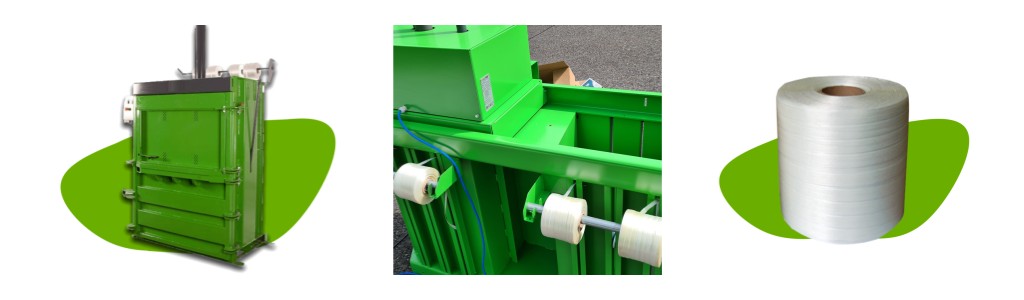

Bale press strapping is a method of bundling materials into compact, secure bales using strong, durable straps. These straps are typically made from materials like polyester, polypropylene, or steel, and they play a critical role in ensuring that materials remain tightly bound during handling, storage, and transportation. In various industries, bale press strapping is used to secure large quantities of materials—often recyclable waste—into manageable units that are easier to move and store.

The strapping is applied using a baler, a machine that compresses the materials into dense bales. This process not only makes the materials more efficient to transport but also ensures that they remain secure and stable throughout the entire supply chain.

While traditional bale press strapping materials often included metals or plastics, modern eco-friendly alternatives are now available, offering the same level of strength and durability while reducing the environmental footprint.

The Rise of Eco-Friendly Bale Press Strapping

The shift towards sustainability in packaging and waste management has led to the development of eco-friendly alternatives for bale press strapping. Many businesses are moving away from traditional plastic or steel strapping due to the environmental impact these materials have—especially when they are not recycled properly. As a result, companies are now turning to sustainable materials that offer similar benefits in terms of strength, durability, and performance.

Eco-friendly bale press strapping solutions typically include materials made from renewable or recyclable sources. These materials are designed to minimize waste and can be fully recycled after use, helping to close the loop in the circular economy. By adopting these solutions, businesses can not only reduce their carbon footprint but also enhance their sustainability credentials, which is increasingly important to customers, investors, and regulatory bodies.

The Importance of Selecting the Right Bale Press Strapping for Sustainability

When selecting the right bale press strapping for sustainable packaging, it’s crucial to consider not only the material used but also the overall efficiency and environmental impact of the entire strapping process. While eco-friendly materials like recycled PET and biodegradable plastics are gaining traction, there are other factors that contribute to a more sustainable approach to waste management. Here are some considerations that go beyond just the material used:

1. Strapping Performance and Durability

While sustainability is a top priority, it’s important to ensure that the chosen bale press strapping is durable and efficient. Strapping must be able to withstand the weight of heavy bales, resist wear and tear during transportation, and ensure that materials remain securely bound without breaking. If strapping fails due to poor performance, it could result in wasted materials, damaged goods, and even safety hazards.

Selecting a high-performance, eco-friendly strapping option ensures that the material is not only sustainable but also effective in securing bales. This reduces the risk of having to replace strapping prematurely, leading to further waste.

2. Strapping Thickness and Design

The design and thickness of the bale press strapping also play a crucial role in both sustainability and functionality. Thicker straps may be necessary for heavy-duty bales, but opting for thinner, efficient designs that still offer adequate strength can help reduce the amount of material used. Strapping that is specifically engineered for strength and compactness can help optimize material usage, thereby reducing waste while maintaining optimal performance.

Advanced technologies in strapping design have led to more efficient materials that require less plastic or other resources without sacrificing the strength needed for industrial applications. This contributes to the overall sustainability of the packaging process.

3. Minimal Waste in Strapping Process

An important but often overlooked aspect of sustainability is the amount of waste generated during the application of strapping. The cutting of straps, excess strapping material, or improper handling can lead to waste that might not be recyclable. To ensure minimal waste, it is essential to choose strapping systems that are designed to maximize efficiency.

Automated strapping systems, for example, can help reduce excess material and improve accuracy in applying strapping. Additionally, businesses can adopt practices that reduce the trimming or handling waste typically associated with the strapping process.

4. Recycling Systems for Strapping Material

A truly sustainable approach to bale press strapping also involves a strong recycling system. It’s not enough for the strapping material to be recyclable; there needs to be a structured plan to ensure it’s properly recycled after use. This means setting up or partnering with waste management services that can collect, process, and recycle the strapping materials once they have been used.

In many regions, recycling facilities are designed to handle specific types of strapping materials, such as PET, and are equipped to break them down into reusable components. Businesses can play a key role in ensuring that their waste is properly sorted and recycled, helping to close the loop on the materials used in their operations.

5. Long-Term Environmental Benefits of Sustainable Practices

Ultimately, choosing the right bale press strapping isn’t just about immediate environmental impact; it’s about fostering a culture of sustainability within an organization. By implementing efficient, eco-conscious strapping methods and materials, businesses can significantly reduce their carbon footprint and align themselves with broader environmental goals.

Companies that prioritize sustainability in their packaging and waste management practices often benefit from long-term environmental advantages, such as reduced dependence on single-use plastics, improved resource efficiency, and a stronger, more positive public image. Consumers and stakeholders are increasingly looking to support businesses that demonstrate a commitment to sustainability, and adopting these practices can contribute to a stronger reputation in the marketplace.

Benefits of Eco-Friendly Bale Press Strapping Solutions

1. **Reduced Environmental Impact**

The most significant advantage of eco-friendly bale press strapping is its reduced environmental footprint. By choosing materials that are recyclable or biodegradable, businesses can significantly reduce the amount of plastic waste they produce. Additionally, the use of renewable resources helps reduce dependence on fossil fuels, contributing to a more sustainable packaging solution.

2. **Cost Savings Through Recycling**

Many eco-friendly strapping materials, such as recycled PET and polypropylene, are often more cost-effective than virgin plastic alternatives. By opting for recyclable or recycled materials, businesses can reduce costs associated with raw material procurement and waste management. The availability of these strapping options in bulk also allows companies to buy at competitive prices, making it a financially sustainable choice.

3. **Enhanced Brand Image and Consumer Trust**

As consumers become more conscious of sustainability and environmental issues, businesses that adopt eco-friendly packaging solutions can improve their brand image. By using environmentally friendly materials for their bale press strapping, companies can demonstrate their commitment to sustainability, which can help build trust with consumers and investors.

A company that prioritizes sustainability may also attract customers who value eco-conscious practices, potentially leading to increased sales and customer loyalty.

4. **Compliance with Regulations**

As governments around the world introduce stricter environmental regulations, adopting eco-friendly solutions like bale press strapping can help businesses stay ahead of compliance requirements. Many regions are now enacting regulations that mandate the use of recyclable or biodegradable packaging materials, and choosing eco-friendly strapping ensures that a business remains compliant with these laws.

5. **Better Waste Management**

Eco-friendly strapping materials can help businesses improve their overall waste management practices. Strapping made from recyclable or biodegradable materials reduces the amount of waste sent to landfills, helping businesses meet sustainability goals and corporate social responsibility (CSR) objectives. Additionally, these materials can be more easily integrated into existing waste management and recycling systems.

Conclusion

Eco-friendly bale press strapping is not just a trend—it's an essential part of the shift towards more sustainable packaging and waste management solutions. By choosing strapping materials that are recyclable, biodegradable, or made from renewable resources, businesses can contribute to the circular economy while improving their operational efficiency.

From reducing environmental impact and costs to enhancing brand reputation and ensuring compliance with regulations, the benefits of eco-friendly bale press strapping are clear. By making the switch to sustainable packaging solutions, companies not only protect the planet but also position themselves as leaders in the growing movement toward sustainability.