In today’s fast-paced industrial and commercial environments, managing waste efficiently is a growing priority. From large manufacturing facilities to small recycling centers, organizations are constantly seeking better ways to reduce their environmental impact, save space, and streamline logistics. Among the many tools used in modern waste management, one often overlooked yet essential component is baling tape.

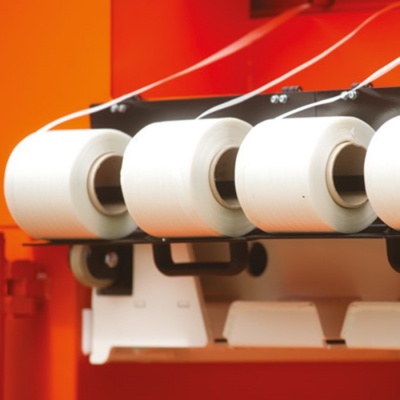

Baling tape, also known as baler tape or hot melt strapping, plays a vital role in securing compressed waste materials such as cardboard, plastic, textiles, and other recyclables. This high-strength, cost-effective solution is designed specifically for use with baling machines and is widely recognized for its reliability, durability, and ease of use.

This article explores what baling tape is, how it works, and why it has become a must-have in effective waste management systems around the world.

Understanding Baling Tape

Baling tape is a type of strapping material designed to secure compacted waste into stable, manageable bales. These bales are typically produced using hydraulic baling machines that compress waste into dense, uniform blocks to optimize storage and transport.

Unlike traditional steel wire, which was once the standard for securing bales, modern baling tape is typically made from high-tensile polyester fibers that are bonded using hot melt adhesives. This construction provides a perfect balance of strength and flexibility, making it suitable for both light and heavy-duty applications.

The Role of Baling Tape in Waste Management

Baling tape plays a central role in optimizing waste handling and processing. Its primary function is to secure waste materials once they have been compressed, ensuring they remain compact and stable throughout handling, storage, and transportation.

Here are the key reasons why baling tape is essential in modern waste management operations:

-Improved Efficiency and Space Saving

By tightly securing waste into uniform bales, baling tape allows facilities to significantly reduce the volume of waste. This leads to better use of available space in warehouses, storage areas, or transport vehicles. Compact bales are easier to stack, move, and store, which translates to increased operational efficiency and cost savings.

-Enhanced Safety and Cleanliness

Loose waste materials scattered across a facility pose safety hazards and contribute to a cluttered working environment. When waste is baled and properly secured with strong baling tape, the risk of falling debris and workplace accidents is minimized. This also helps maintain a cleaner, more organized space.

-Simplified Handling and Logistics

Once compressed and strapped, bales are more manageable and can be easily handled using forklifts or pallet jacks. The consistency provided by baling tape ensures that bales do not fall apart or lose shape during loading and unloading, reducing the risk of transport delays or product damage.

-Support for Recycling and Sustainability Goals

Baling waste for recycling is an important step in supporting sustainability. Securely strapped bales are easier to sort, process, and recycle. Whether it’s cardboard, PET bottles, or plastic film, baling tape helps preserve the integrity of recyclable materials until they reach their final processing destination. This contributes to lower landfill usage and promotes circular economy practices.

-Reduced Packaging Costs

Using baling tape eliminates the need for more expensive and heavier alternatives such as metal wires or bulk containers. It is lightweight, easy to handle, and relatively low-cost, making it a more economical choice for businesses seeking to improve their waste packaging systems.

Key Advantages of Baling Tape

Baling tape offers a range of technical and operational benefits that make it the preferred choice in many industrial and commercial settings.

-High Tensile Strength

Despite being lightweight, baling tape is incredibly strong. It can handle high tension loads without breaking, making it suitable for compressing dense and heavy materials.

-Elastic Memory

Unlike steel wire, baling tape has a certain level of elasticity that allows it to absorb shock and vibration. This flexibility helps it maintain tension even if the contents of the bale shift slightly, which is especially useful during transportation.

-Corrosion and Weather Resistance

Being made from polyester materials, baling tape does not rust or corrode like metal alternatives. It is also resistant to UV radiation, humidity, and temperature changes, making it suitable for outdoor use or storage in variable environmental conditions.

-Operator Safety

Using baling tape reduces the risk of injury compared to steel wire, which can snap or cause cuts. It is safer to handle and does not require gloves or special cutting tools, making the work environment safer for employees.

-Ease of Application

Baling tape is compatible with automatic and semi-automatic balers and is easy to feed, cut, and tension. This speeds up the baling process and reduces downtime, especially in high-volume operations.

Applications of Baling Tape

Baling tape is used across various industries that produce large volumes of waste or recyclables. Some common application areas include:

- Retail and supermarkets for packaging cardboard boxes and plastic wrap

- Manufacturing plants for baling scrap materials, plastics, and metal trimmings

- Recycling centers for processing paper, PET bottles, and other recyclable streams

- Printing facilities for managing offcuts, trimmings, and paper waste

- Logistics warehouses for packaging return goods or damaged packaging materials

Each industry benefits from the versatility and strength of baling tape in managing waste efficiently and safely.

Best Practices for Using Baling Tape

To get the best performance and safety from baling tape, it is important to follow some best practices:

- Choose the right tape for your baling machine and waste type

- Always check the tensile strength and recommended usage of the tape

- Inspect tape for damage or irregularities before use

- Ensure the tape is tensioned correctly to avoid loose bales

- Store tape in a dry, cool place away from direct sunlight or chemicals

Conclusion

In the pursuit of more sustainable, safe, and cost-effective waste management solutions, baling tape has proven to be a powerful ally. Its strength, reliability, and versatility make it an indispensable part of daily operations for countless businesses around the world.

From reducing space and improving logistics to supporting recycling efforts, baling tape delivers tangible value at every stage of the waste handling process. As environmental regulations tighten and the demand for efficient waste solutions increases, adopting high-quality baling tape is not just a smart move—it is a necessary one.

Whether you run a recycling center, a warehouse, or a manufacturing facility, investing in the right baling tape will help you meet your waste management goals with greater confidence and consistency.